The world's smallest direct drive motor

Discover the advanced hollow micro direct drive motor designed for high-performance automation.

List

All μDD motors have a space-saving (compact) design and are capable of high-torque and high-accuracy positioning.

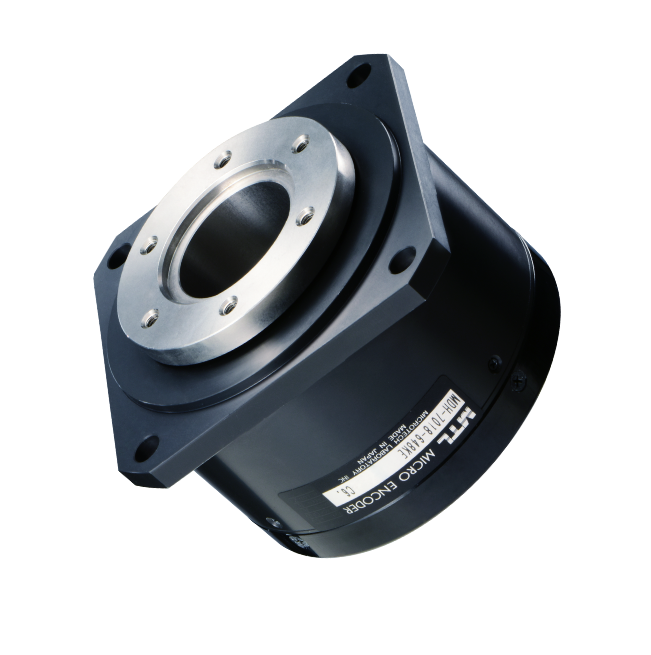

MDS13

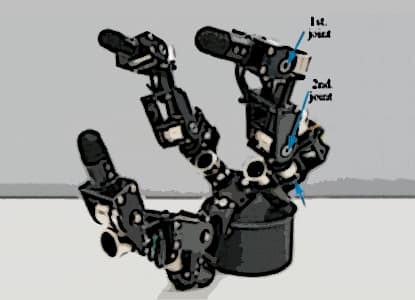

The world's smallest direct drive motor. Perfect for lightweight applications such as grippers and robotic hands handling.

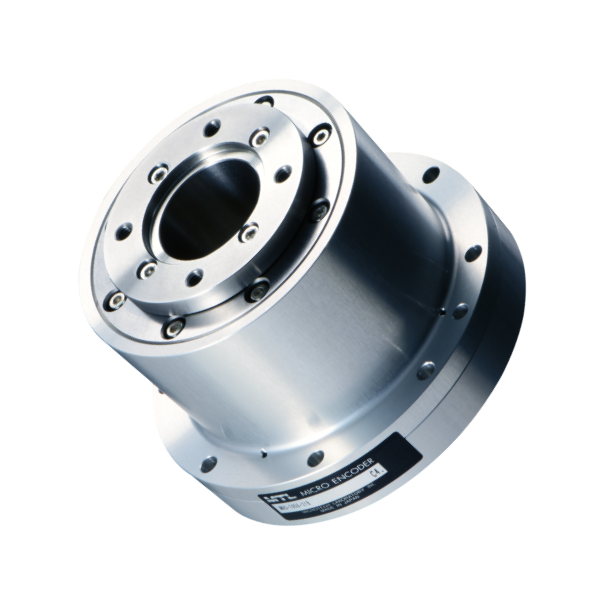

The world's smallest hollow-shaft servo motor. Ideal for end effectors, small robot hands, and low reduction ratio gear setups.

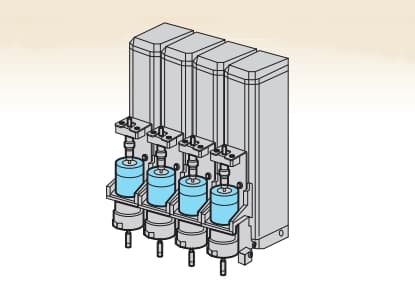

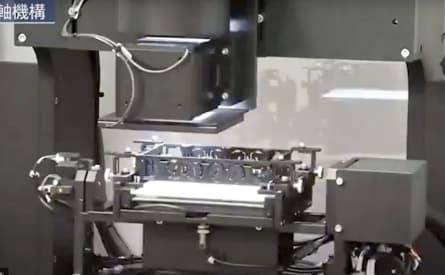

Perfect for high-precision dispensing and small gimbal drives with precise motion control.

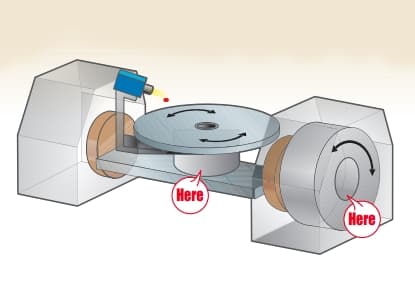

Features a large inner diameter (φ12 mm), allowing for integration of cables, lasers,etc.

A compact motor with a large hollow shaft (φ20 mm), ideal for end effectors and robot joints.

Designed for rotary actuators, index tables, and robotic arm joints (elbow and shoulder).

Advantage

This product has features that only a manufacturer specializing in rotary encoders can offer.

We have achieved a compact, hollow design while retaining the advantages of a conventional DD motor.

About

A hollow shaft motor is a type of motor with a through-hole in the center of the motor's structure, providing enhanced design flexibility. The hollow core allows for the passage of various components such as cables, air tubes, lasers, and other necessary equipment. This design not only saves valuable space but also improves the precision and efficiency of the system by minimizing clutter and reducing the need for additional external parts.

Support

At Microtech Laboratory, we provide comprehensive support across all stages of your μDD motor journey.

Our service includes:

Choosing the right motor and drive is crucial for your application. Whether you're uncertain about the best combination or need assistance with specific parameters, we're here to help.

Manual tuning allows you to further optimize the settings.

To maximize the performance of your μDD motor, we offer manual tuning options, allowing you to adjust settings for optimal operation.

・Paid Tuning by MTL Engineers: If you require expert-level tuning, our engineers can help you fine-tune your system for peak performance.

・Flexibility: You can continue using the driver you're currently using, ensuring a seamless integration with your existing equipment.

We stand by our products with a rigorous quality assurance system. Our support doesn't end after the sale you're backed by continuous technical support and thorough product testing.

・Technical Support: Should you have any questions or need assistance, feel free to reach out.

・Product Testing: Each motor undergoes strict quality checks to ensure it meets our high standards.

Feel free to reach out to us.

Introduction

Characteristics: High torque, ultra-compact, hollow shaft, light weight

high torque

ultra small

hollow shaft

light weight

Characteristics: High torque, high accuracy, no backlash (high response), high rigidity

high torque

high percision

no backlash

high rigidity

Characteristics: High torque, ultra-compact,holloe dlameter, high backdorivability

high torque

ultra small

hollow shaft

high backdrivability

Feel free to reach out to us.

Flow

FAQ

We provide a motor selection tool to assist with this process.

Please have the motor load details ready, including factors such as:

Feel free to reach out to us.

At Microtech Laboratory Inc., we take pride in creating innovative solutions that did not exist before, enhancing the value of our customers' equipment. With a focus on precision assembly technology, we specialize in the development, manufacturing, and sales of ultra-compact products that push the boundaries of innovation.

We have established a production system that delivers high-quality products at low costs. The specifications we provide are guaranteed values, factoring in safety margins to ensure reliability. Additionally, all components are sourced from Japan, ensuring a stable supply chain and maintaining our high standards.

In our design process, we continuously verify ideal values and the feasibility of each product to ensure both quality and functionality. Our manufacturing system reflects this meticulous approach, resulting in products that meet and exceed expectations.

Our products undergo rigorous testing and are monitored under a strict quality assurance system. Should any defects arise, we offer a free replacement, providing our customers with peace of mind and complete satisfaction.

Company

Feel free to reach out to us.

Please contact us

We are working hard to prepare the English version of the document. Please wait a little longer.