Microtech Laboratory for small direct drive motors

MDS/MDH-30Series

Tapping the hollow shaft and being installed rotary joints, it can be penetrated air tubes and cables.

- Body diameter:φ30mm

- Body length:31.5/37.5/43.5mm

- Max torque:140/280/420mN・m

- Max speed:1,000rpm

- Max resolution:432,000P/R、19bit

- Hollow diameter:φ4mm(MDH type)

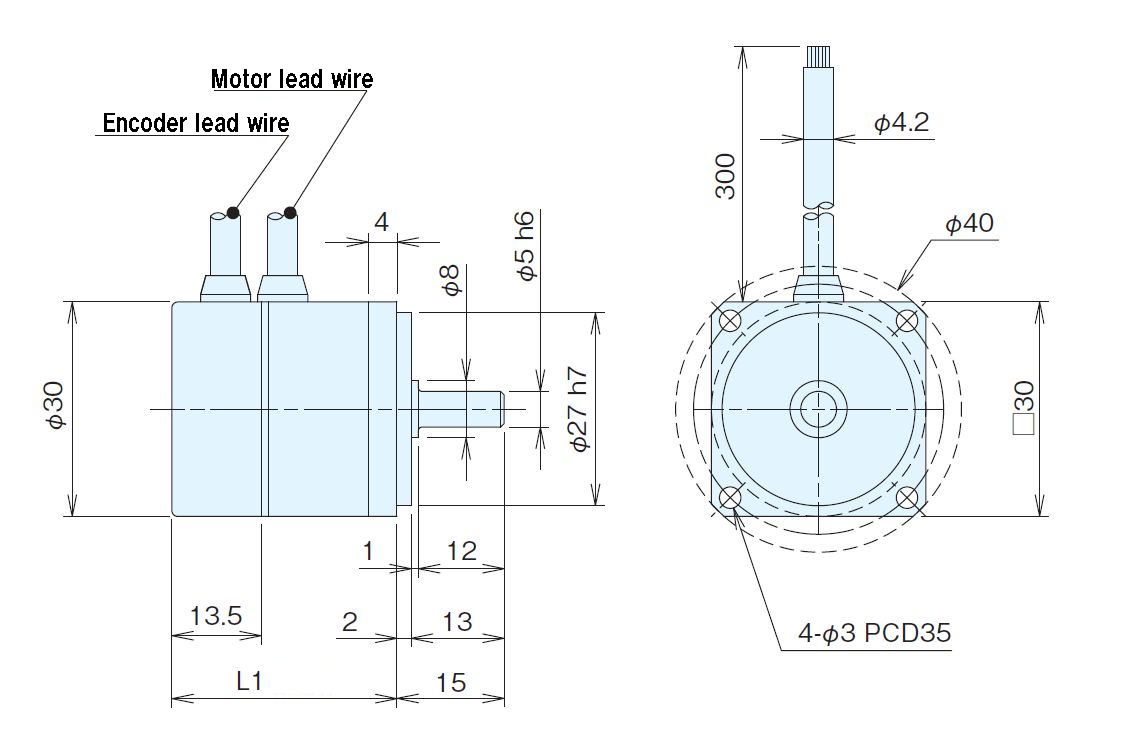

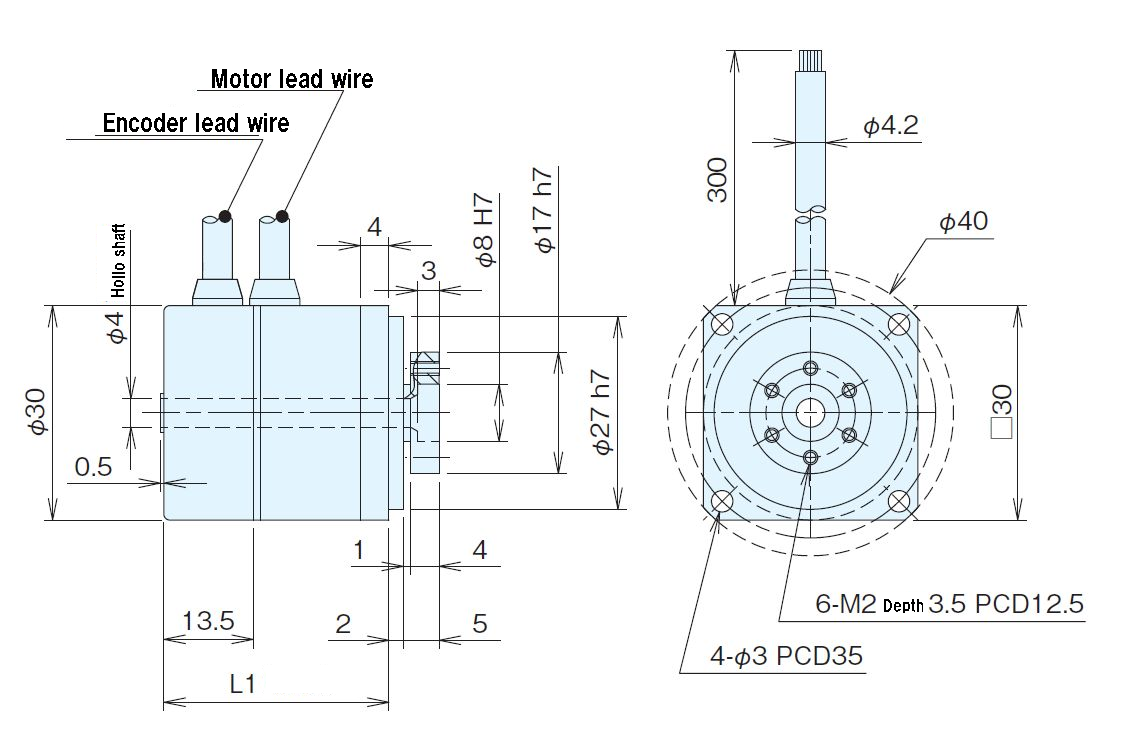

Outer dimensions

MDS-30

MDH-30

Specification

| Model | L1 dimention |

|---|---|

| MD□-3006 | 31.5 |

| MD□-3012 | 37.5 |

| MD□-3018 | 43.5 |

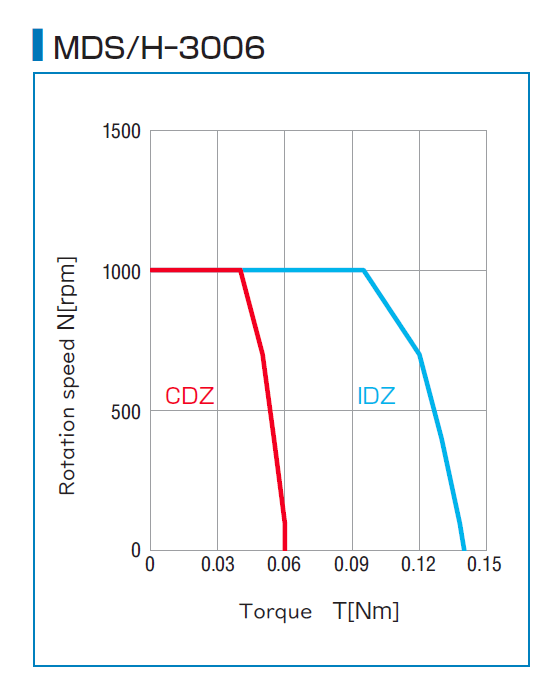

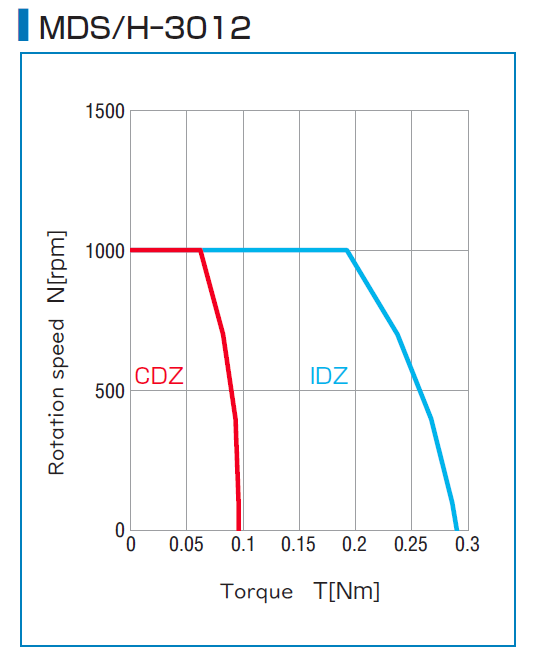

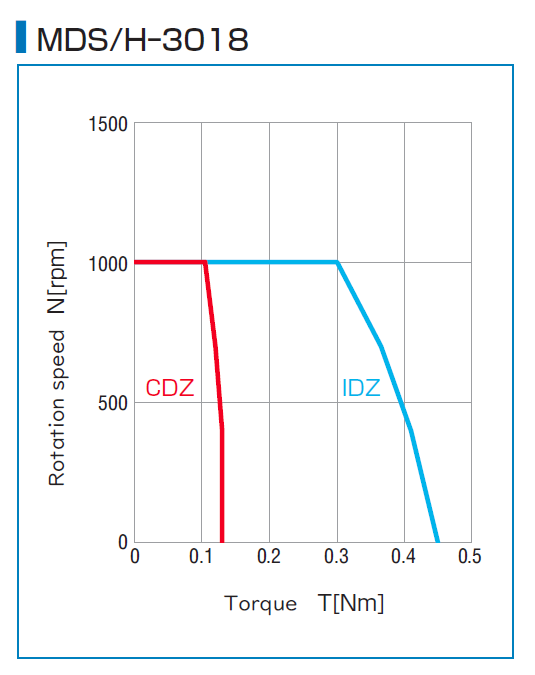

Examples of speed and torque characteristics

MDS/H-3006

MDS/H-3012

MDS/H-3018

【Postscript】

The maximum rotational speed is limited by the encoder's response frequency, but the speed range can be further increased by reducing the encoder resolution.

| Unit | MDS-3006 | MDH-3006 | MDS-3012 | MDH-3012 | MDS-3018 | MDH-3018 | |

|---|---|---|---|---|---|---|---|

| Input power (Driver input) | DCV | 24(※1)/48 | |||||

| Maximum speed (※2) |

rpm | 1000 | |||||

| Rated speed | rpm | 1000 | |||||

| Peak torque at stall | Nm | 0.14 | 0.28 | 0.42 | |||

| Rated torque | Nm | 0.060 | 0.095 | 0.13 | |||

| Continuous rated torque | Nm | 0.044 | 0.068 | 0.10 | |||

| Peak power | W | 15 | 20 | 30 | |||

| Peak power rate | kW/s | 31 | 23 | 71 | 60 | 110 | 98 |

| Peak armature current | Arms | 4.6 | 5.6 | 6.3 | |||

| Rated armature current(※3) | Arms | 1.8 | 1.8 | 1.7 | |||

| Voltage constant | V/krpm | 2.8 | 4.5 | 6.8 | |||

| Torque constant(at25℃) | Nm/Arms | 0.026 | 0.043 | 0.065 | |||

| Line armature resistance(at25℃) | Ω | 2.1 | 2.3 | 2.5 | |||

| Line armature impedance | mH | 1 | 1.3 | 1.5 | |||

| Rotor Poles | P | 16 | |||||

| Max encoder resolution(※4) | P/R | Incremental:432,000(After 4 multipliers) Absolute:524,288(19bit) |

|||||

| Moment of inertia J | g・cm^2 | 6.5 | 8.9 | 11.2 | 13.6 | 15.9 | 18.3 |

| Permissible radial load Fr | N | 94 | |||||

| Permissible axial load Fa | N | 47 | |||||

| Allowable moment | Nm | 2.92 | 2.74 | 3.44 | 3.27 | 3.96 | 3.78 |

| Repeated positioning accuacy at shuttling | パルス | ±1 | |||||

| Mass | kg | 0.13 | 0.16 | 0.18 | |||

| Applicable motor driver | MC-200-7220▢ / MC-200C-6018▢ | ||||||

| Standard heat sink | 120×120×8 Alminum | ||||||

【Note】

(※1) In case you use with, please contact us since peak torque would change.

(※2) Please ask if there is a speed you prefer.

(※3) Rated armature current is the value measured with the standard heat sink attaxhed to the motor at an ambient temperature of 40℃ .

(※4) Please ask if there is a particular resolution you prefer.

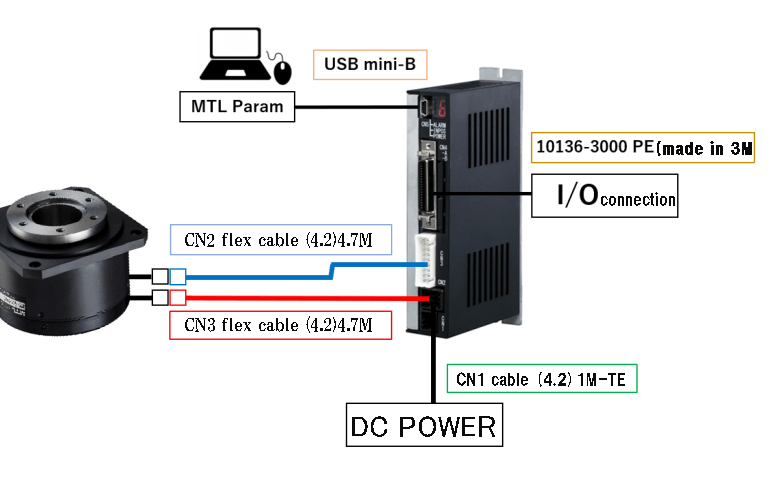

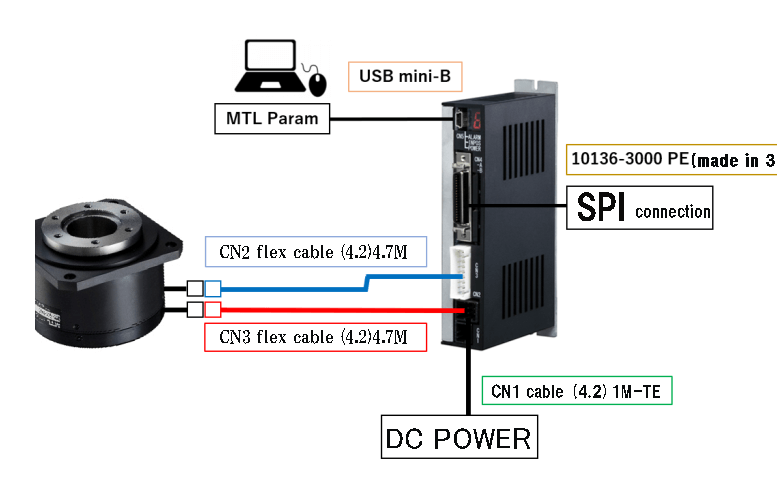

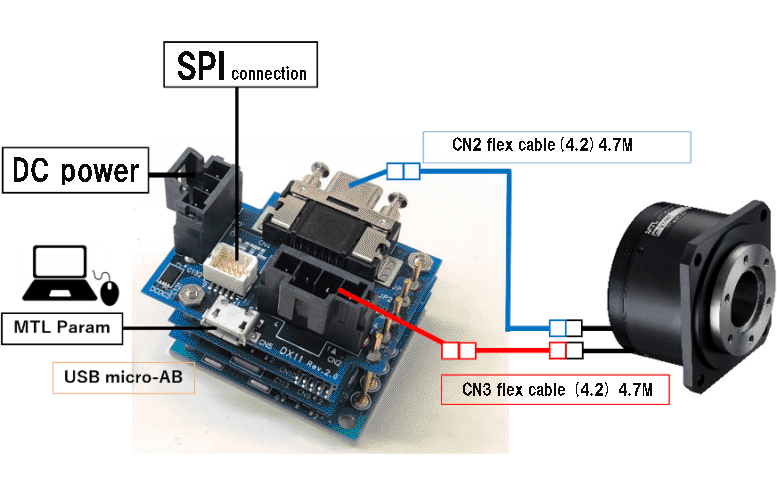

Cable options

| Model | Connection |

|---|---|

| CN1 cable(4.2)1M-TE | Between power and driver(1m) |

| CN2 bent cable(4.2)0.7M | Motor cable:Extension between motor and driver (Total1m) |

| CN2 bent cable(4.2)2.7M | Motor cable:Extension between Motor and Driver(Total3m) |

| CN2 bent cable(4.2)4.7M | Motor cable:Extension between motor and driver(Total5m) |

| CN3 bent cable(4.2)0.7M | Encoder cable : Extension between motor and driver(Total1m) |

| CN3 bent cable(4.2)2.7M | Encoder cable : Extension between motor and driver(Total3m) |

| CN3 bent cable(4.2)4.7M | Encoder cable : Extension between motor and driver(Total5m) |

| CN5 cable | USB2,0 cable with ferrite core : Between PC and driver(1m) |

※Please prepare the CN4 connector cable of the MC-200 by the user.

※MC-200C CN1/CN4 connector cable and CN2/CN3 conversion connector cable are included.

Example of the use

MC-200-7220A

MC-200-7220D

MC-200C-6018D

After-sales service

How to request repair

About the Warranty coverage

In the event of a failure due to our responsibility, we can repair and replace the product for free within the warranty period.

However, The warranty is by the product,so expenses with parts replacement and compensation for damages(etc) is out of the application of our warranty.

About the case where the warranty does not apply

As a result of inspection, if it is found that the product is not a malfunction but handling or an external influence, you will be charged even during the warranty period.

The warranty period

Within 1 year after the start of use (however, within 1.5 years after delivery).

Click here for Inquiries

Open Monday-Friday.

9:00 am to 5:30 pm.