Microtech Laboratory for small direct drive motors

About μDDmotor(direct drive motor)

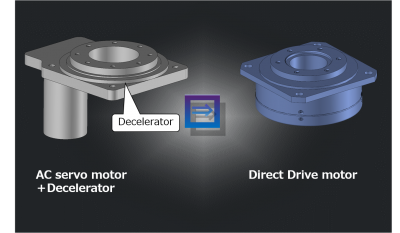

What is DD motor?

What is DD motor?

DDmotor is the servo motor that has high acceleration and positioning,

Which also specialized in using for gearless.

DDmotor has characterristics of low speed and high torque (compared to general servo motors) because this motor is assumed that it will drive directry without using a gear(a deceleration mechanism).Its equipped sensor specialized in high-precision positioning, and It is possible to receive the shaft load directly by adopting high-load bearing as standard.

Advantages that can be generally obtained by using a gearless structure are described below.

This motor leads noise reduction since it has

no vibraition sound.

It is possible to determine high precision

positioning by eliminating a machanical error

due to backlash.

It is a characteristic that is advantageous when

an operator provides tactile feedback for master-slave control.

What is μDDmotor?

What is μDDmotor?

It’s the world`s smallest direct drive motor!

MTL has the strength unique to manufacturers specialized in a rotary encoder.

We have realized small sized and hollow shaping while retaining the goodness of the conventional DD motor.

High torque

About 5 times torque density

(compared to AC servo mortor as

standard)

Ultra compact size

The world`s smallest class

(compared to DD mortor as

standard)

Hollow shaft

Hollow late 35%

(it`s a top class in theservo

motor industry)

Product lineup

Product lineup

We have a rich lineup of small direct drive motors.

|

|

|

|

|

The world's smallest in |

New products that have high torque and hollow rate 30% despite its small size. |

Maximum outer dismeter and hollow rate. |

|

Case studies and customizing unique to μDDmotors

Case studies and customizing unique to μDDmotors

Double-armed robot

that transmits bodily sensations

「GP-Arm」

It can share force tactile and visual information with a robot in a distant place in real time.In the future, it will maybe become an avatar and be possible to directly teach not only location information but adjustment and visual information.

User:NEDO/Keio University Haptics Research Center

Keio University Haptics Research Center

Tap in the hollow shaft μDD motor

A rotary joint can be connected using a tap.

This is the best in rotational drive and fixation by sucking on index table, and it is also used in a end effector to transport small parts.

FAQ

FAQ

Product Specifications and hou to buy etc...

If you would like to see the frequently asked question, please go to the right.

After-sales service

After-sales service

After-sales service is the two, Analysis of the malfunction and repair surport.

How to request repair

About the Warranty coverage

In the event of a failure due to our responsibility, we can repair and replace the product for free within the warranty period.

However, The warranty is by the product,so expenses with parts replacement and compensation for damages(etc) is out of the application of our warranty.

About the case where the warranty does not apply

As a result of inspection, if it is found that the product is not a malfunction but handling or an external influence, you will be charged even during the warranty period.

The warranty period

Within 1 year after the start of use (however,within 1.5 years after delivery)

Flow until delivery

Flow until delivery

Standard models

Custamaized pruducts

Please tell us the required specifications.

We will propose the most suitable model.

We will check the specific specifications and ask the orderer about the purpose for use deeper.

Click here for Inquiries

Open Monday-Friday.

9:00 am to 5:30 pm.