小型ダイレクトドライブモータのマイクロテック・ラボラトリー

- 小型ダイレクトドライブモータのマイクロテック・ラボラトリー

- ENGLISH

- HAPTIC HAND DEMO

HAPTIC HAND DEMO

Contents

1.What is Kashokuka?

2.About Kashokuka Device?

Introduction Video

Component Composition

3.What is Leader-Follower Control?

What is Bilaretal

4.Product Benefit?

5.What is the reason to build a leader-follower with reaction force detection with a simple

configuration ?

6.Lastly

What is Kashokuka?

Kashokuka (Telerobotics)is a technology that enables people to "communicate" and "feel" more remotely using bilateral devices.

About Kashokuka device

The device will reproduce Kashokuka.

It will provide tactile control for tele-operation, and minute to dynamic feedback!

Furthermore, it enables intuitive touch, expanding further possibilities for remote control and communication.

We exhibited a parallel link type device at the 2022 International Robot Exhibition.

For more details, please refer to the introductory video below!

Parallel-link type Kashokuka Device (L: Leader, R:Follower)

Parallel-link type Kashokuka Device (L: Leader, R:Follower)Kashokuka devices introduction video

Parallel-link Kashokuka Device : Main Parts Configuration

Motor ・Driver・Controller・Mechanical Part・Power Supply・The Kashokuka device has a simple configuration

| Device | No.Unit | Product Name | Remark | |

| 1 |

12 |

Small hollow large-diameter Direct Drive Motor |

Outer DIAφ70mm、 |

|

| 2 |

12 |

Small servo driver |

Host Signal:SPI |

|

| 3 |

Raspberry Pi4 |

2 |

Raspberry Pi4 |

Single Board Computer |

※No.Unit is the total of both leader&follower

We can assist anyone interested in Kashokuka and leader-follower!

I want to try it out, touch and grab a robot like this.

It started from request like this.

We can develop a prototype of your desired tactile device based on your request!

What is leader-follower control?

It is one of the replacement terms for master-slave control.

When the "leader" is operated, the "follower" performs a cooperative action.

In a parallel-linked Kashokuka device, the leader side is operated by hand, and the follower side performs the same movement.

Furthermore, the device is equipped with bilateral control, so that the feeling of the object being grasped on the follower side is transmitted to the leader side.

Thus, intuitive remote control is possible.

What is bilateral control?

Unilateral" is a term used to describe a master-slave position-controlled system that has been widely used in teleoperation.

In contrast, a system that adds force control to position control and controls both the master and slave is called "bilateral.

(Reference:北海道立工業試験場報告「バイラテラル方式による力覚制御技術」)

The operator (leader) receives the force received by the remote follower (force tactile feedback is provided to the operator), and this allows the operator to more intuitively control the device.

What kind of device is used for leader-follower control?

EX1: High branch pruning scissors (Mechanical Leader-Follower)

The operator can feel the cut, so "with reaction force feedback"

EX2: Mouse (pointing device)

Mouse is the reader, pointer is the follower.

When the pointer hits the edge of the screen, the mouse does not feel it, so "no reaction force feedback."

EX3: The da Vinci surgical robot

Example of leader-follower application.

The doctor operates the leader, and the follower operates accordingly.

In conventional surgery, an incision is made as much as necessary to secure the field of view and the area to be treated.

The endoscope secures the field of view, and the da Vinci's follower mechanism is designed to be thinner and longer than a human hand.

This reduces the extent of the required incision.

Ex4 Real haptics artificial hand

The leader is a foot pedal, and the follower (prosthetic hand) operates according to the amount of depressing.

Force tactile sensation touched by the artificial hand is fed back to the foot pedal to control the hand

What can we do with leader-follower control?

・Remote control

・Tele-operation

Since the reader and follower need only be electrically connected, the system works not only with wired connections but also with wireless connections.

Delay occurs in proportion to the distance, but this is expected to improve as communication speeds increase.

・Scaled tele-operation/micro manupilation

Delicate work on the order of microns that cannot be handled directly by humans, orOperations such as lifting heavy objects weighing many tons can be performed via the leader follower system.

リーダーフォロワー(マスタースレーブ) システム構成例

Leader Follower (Master-Slave) System Structure

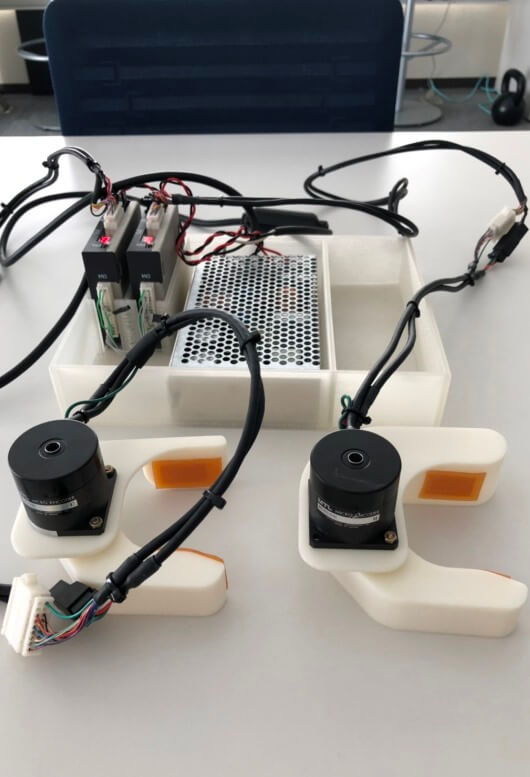

学生が製作した反力フィードバックを有するマスタースレーブ ハンド

Master-slave hand with reaction force feedback constructed by a student

使用部品 Components

①μDD Motor:MDH-4018-324KE ×2

②Specialized Driver:MC-110-4810 ×2

③Master-Slave Cable ×1

④Power Supply48V ×1

⑤Hand (Made with 3D Printer)

組み立て手順 Assembly Instruction

(1)モータとドライバをコネクタ接続する。マスター用、スレーブ用の2セット

Connect the motor and driver to the connector. 2 sets for Master and Slave

(2)ドライバ間をマスタースレーブ用ケーブルで接続する。

Connect the Master-Slave Cable to the driver.

(3)電源を供給し、マスタースレーブ 可能が可能。

Turn on the power supply, Master-Slave is ready to use.

(4)ゲイン調整(位置決め精度や反力フィードバックを最適化するためのチューニング)

Gain adjustment (For a better positioning accuracy and reaction force feedback)

シンプルな構成で反力検出を有するリーダーフォロワーを構築可能な理由とは?

Why it's possible to construct a leader-follower with reaction force detection in a simple configuration?

良好なバックドライバビリティ High Backdrivability

外力により生じる出力関節の回転の度合いを示すもので、動力伝達機構や減速比などにより変化します。It indicates the degree of rotation of the output joint caused by an external force, which changes depending on the power transmission mechanism, reduction ratio, etc.

一般に産業用ロボット・マニピュレータのようにこう減速比のギヤを用いると出力関節に現れる摩擦力や

In General, using gears with this reduction ratio,such as in industrial robot manipulators,

increases the frictional and inertial force appear at the output joints. resulting in poor backdrivability

慣性力が大きくなり、バックドライバビリティは悪化します。

高減速比ではバックドライバビリティは悪化するが、低減速比になるほどバックドライバビリティは改善します。

Backdrivability worsens at high reduction ratios,but with lower reduction ratio backdrivability will improve.

高トルクHigh Torque

減速機は主にトルクを増幅する目的で使用しますので、ギアを低減速比化したいが、必要トルクに満たない場合は低減速化は叶いません。

Reduction gears are mainly used to amplify the torque, If reduced gear ratio is necessary, but the required torque is insufficient, the reduction in speed cannot be achieved.

モータ自体が高トルクだから減速比を小さくできます。

Since the motor itself has High-Torque enable a smaller reduction ratio.

減速比が小さくなるとバックドライバビリティが向上します。

Smaller reduction ratio improves backdrivability.

バックドライバビリティが向上すると、スレーブで受けた触覚を、操縦者が受け取りやすくなります。

Improved backdrivability makes it easier for the operator to feel the tactile sensations received by the slave.

To wrap things up

少しだけ製品紹介にお付き合いください。

Please allow us a few moments to introduce our products.

μDDモータは同サイズ比5倍の最大トルク。バックドライバビリティの向上に役立つはずです。

μDD motor has 5 times maximum torque compared to the same size. It should improve back drivability.

μDDモータを使用したリーダーフォロワー(マスタースレーブ)ロボット

Leader-follower (master-slave) robot using μDD motors

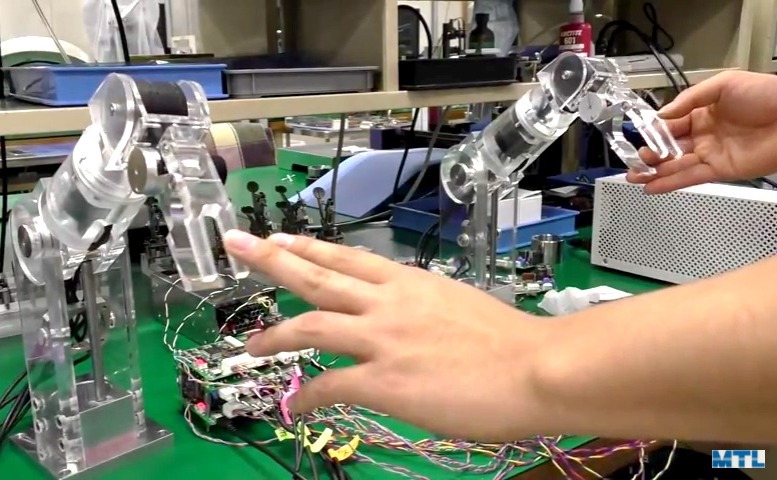

3軸ロボットアームのマスタースレーブ

3-Axis Master-Slave Arm

MTL社内デモ機です。

MICROTECH LABORATORY Demonstration Unit

リアルハプティクス義手

Real Haptic Artificial Arm

A prosthetic hand that transmits force in both directions between the prosthetic hand and the foot pedal = force-tactile implantation.

Better than the ON/OFF operation with myoelectric prosthetic hands,

Exquisite force can be adjusted.

ユーザ:慶應義塾大学 野崎研究室

User: Nozaki Laboratory, Keio University

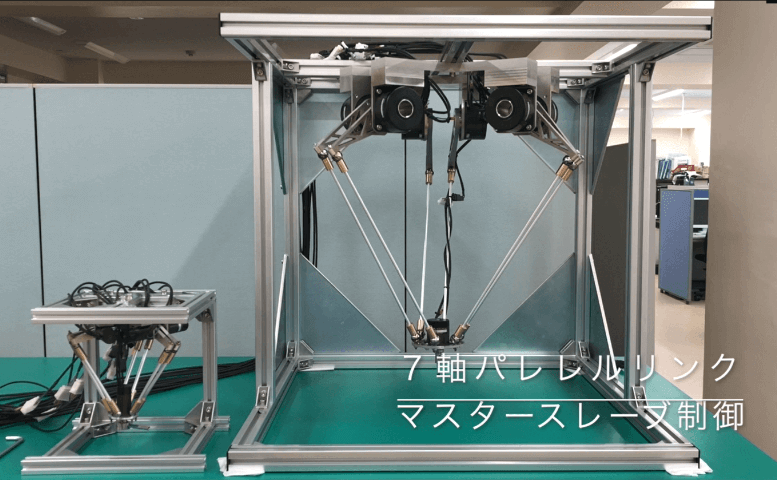

7軸パラレルリンクマスタースレーブ

7-Axis parallel link master-slave

μDDモータでパラレルリンクロボットを作りました。We Construct Parallel link robot with μDD Motor

シンプル構成で摩擦が少なく、軽い操作感が特徴です。

The simple configuration features low friction and a light operational experience.

MTL社内デモ機です。

MICROTECH LABORATORY Demonstration Unit

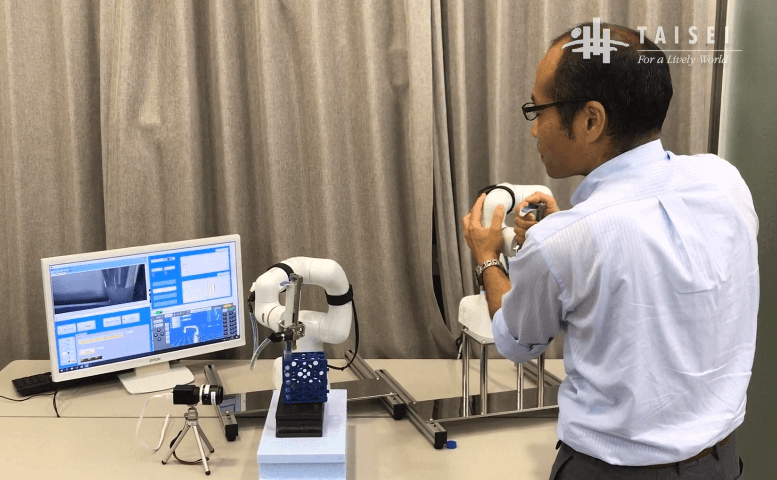

細胞培養操作向け遠隔操作システム

Remote control system for cell culture operations

ピペットの微細な操作を、触覚フィードバック付きで無線遠隔操作が可能となりました。Fine manipulation of pipettes can now be performed wireless remote control with tactile feedback.

協働ロボット同士もマスタースレーブ動作をしています。

The cooperating robots also operate in master-slave mode.

ユーザ:大成建設株式会社様

User: Taisei Corporation

身体感覚を伝送する双腕型ロボット:GP-Arm

Dual-armed robot transmits physical sensations

力触覚や視覚情報を、遠くの自分(ロボット)とリアルタイムで共有します。将来は自分がロボットとなり、位置情報のみならず、力加減や視覚情報をダイレクトティーチングできるようになります。Force tactile and visual information is shared with your remote self (robot) in real time. In the future, you will be the robot, and you will be able to directly instruct not only positional information, but also force and visual information.

ユーザ:NEDO/慶應義塾大学ハプティクス研究センター

慶應義塾大学野崎研究室

User: NEDO/Keio University Haptics Research Center

Nozaki Laboratory, Keio University

Avatar Fishing -Remote Fishing Experience-

東京都⇔大分県にてマスタースレーブ。Master slave in Tokyo⇔Oita Pref.

釣り糸の引張感、リールの巻取り抵抗がリアルタイムで感じることができ、大分名物鯛釣りを東京で体験できます。

You can feel the tension of the fishing line and the resistance of the reel in real time, allowing you to experience Oita's famous sea bream fishing in Tokyo!

釣った鯛は、航空便で翌日には届くサービスを検討中。

We are working on a service where the sea bream will be delivered the next day by airmail.

ユーザ:株式会社Re-al様

ANAavatarin様

User: Re-al Corporation様

ANAavatarin様

参考資料

Reference Materials

参考文献 Articles

ROBOTICS ロボティクス 日本機械学会(著者名 一般社団法人 日本機械学会 発表年2011年9月15日 タイトル ROBOTICS ロボティクス)

https://www.jsme.or.jp/

Reference Link

東京医科歯科大学病院 手術支援ロボット「ダヴィンチ」徹底解剖http://hospinfo.tokyo-med.ac.jp/davinci/charm/index.html

日本ロボット学会誌

ロボットとアクチュエータのバックドライバビリティ(岡山大学 鈴森康一氏)

https://www.jstage.jst.go.jp/article/jrsj/31/6/31_31_548/_pdf

製品のお問い合わせはこちら

042-746-0123

受付 / 平日9:00~17:30